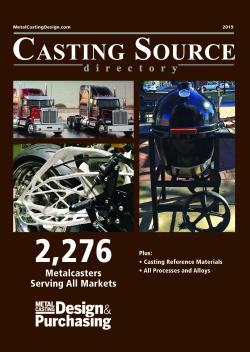

2019 Casting Source Directory: Click for the full digital edition of the 2019 Casting Source Directory issue.

Guide to Casting and Molding Processes:

The versatility of metalcasting is demonstrated by the number of casting and molding processes currently available. This range of choices offers design engineers and component users flexibility in their metal forming needs.

Rapid Metalcasting Methods:

Rapid manufacturing bridges the gap from prototype to production and opens doors to design flexibility.

Iron Alloys:

Iron castings are produced by a variety of molding methods and are available with a wide range of properties. Cast iron is a generic term that designates a family of metals that include gray, ductile, austempered ductile, carbidic austempered ductile, compacted graphite, malleable, white and alloyed irons.

Steel Alloys:

Steel castings are used in a variety of end-use applications that require heavy-duty components. The castings are used in railroad cars, pumps, valves, heavy trucks, construction and mining equipment, and power generation units.

Aluminum Alloys:

Cast aluminum has seen significant growth during the past two decades, largely a result of automakers’ need to lighten their vehicles to improve gas mileage. However, the material also has found its way into other industries, from kitchen utensils to high-strength aerospace components.

Copper Alloys:

Cast copper alloys are known for their versatility. They are used in plumbing fixtures, ship propellers, power plant water impellers and bushing and bearing sleeves because they are easily cast, have a long history of successful use, are readily available from a multitude of sources, can achieve a range of physical and mechanical properties and are easily machined, brazed, soldered, polished or plated.

Magnesium Alloys:

Cast magnesium alloys have the ability to maintain high strengths at light weights. Magnesium possesses properties that can open the door to structural applications and has gained widespread use in automotive components.

Zinc Alloys:

Zinc casting alloys most often are diecast—a process in which molten metal is injected into metal molds at high pressure—because it provides the material with optimum surface finish and an ability to produce complex parts at a reduced cost.

Glossary of Metalcasting Terms :

A key to finding the best casting is understanding the words and phrases of the industry.

Trade Associations:

Trade associations are an important part of the metalcasting community.

Website Spotlight:

Website Spotlight is a directory designed to provide easy access to information from today’s leading suppliers.

Geographic Listing:

This link provides a guide to the metalcasting operations of North America.

Metals Cast:

To find a reliable source by metals poured, follow this link.

Casting Process:

To find a reliable source by casting process, follow this link.

Issue Date